Global Brands. Proven Performance.

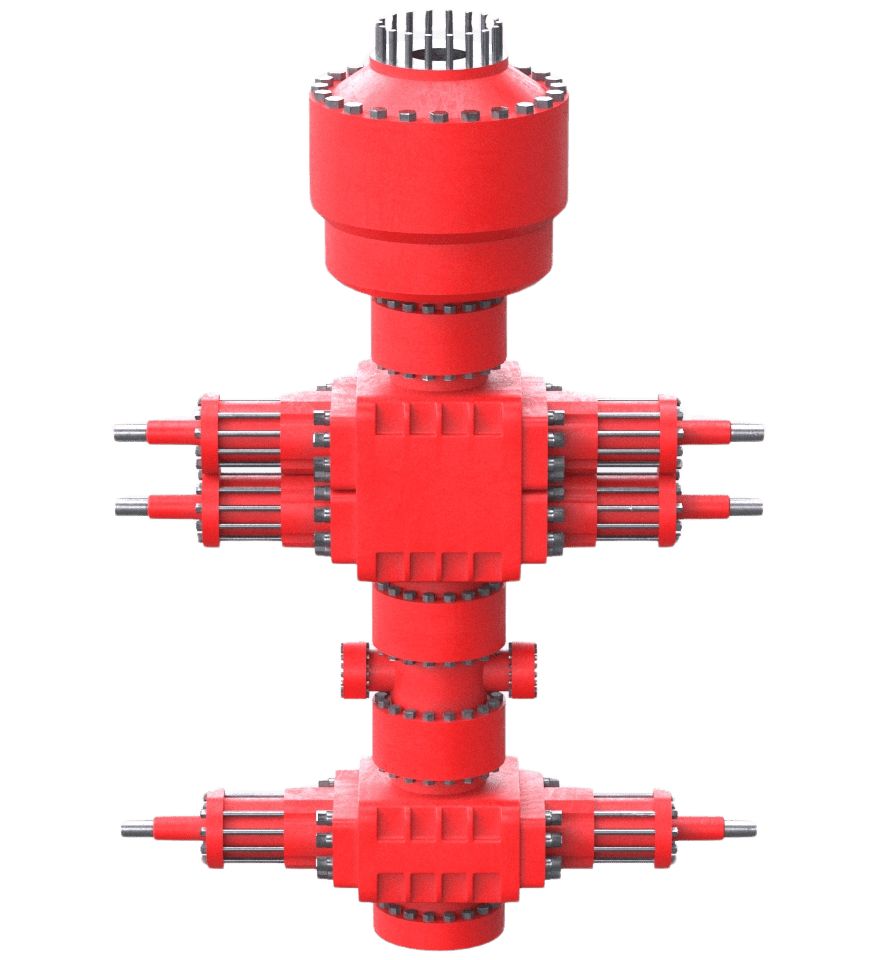

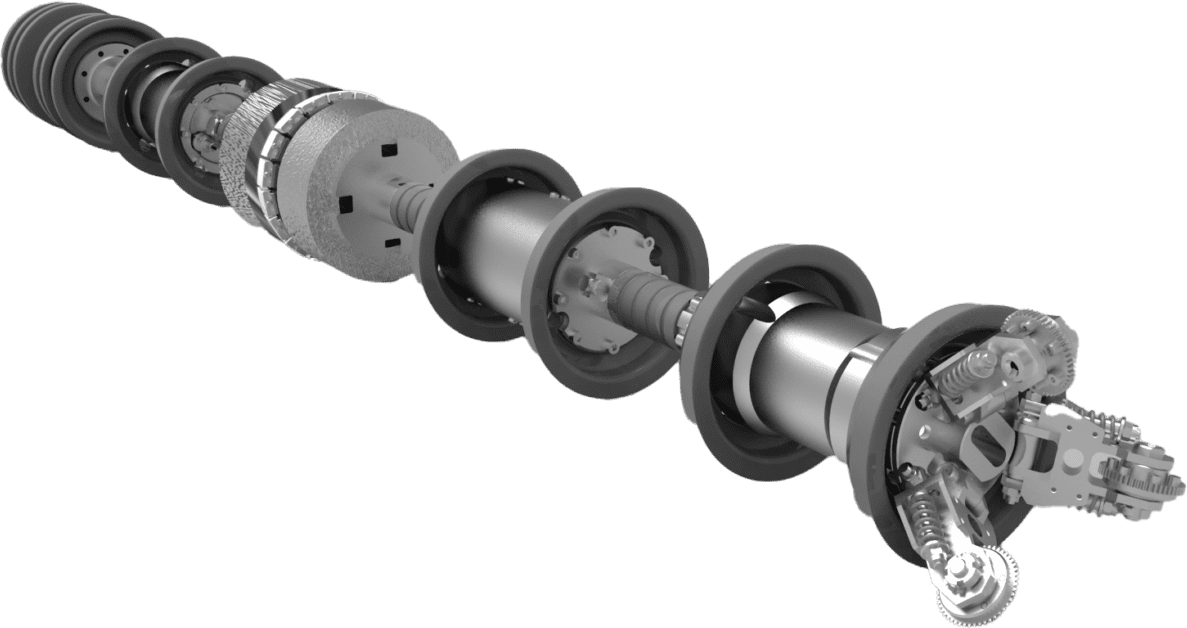

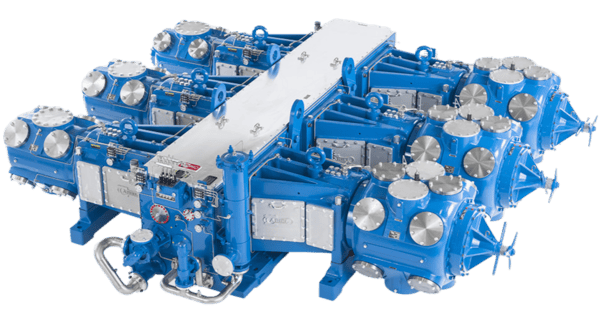

We supply advanced blowout preventers, top drives, rotary tables, and mud pumps engineered for high-pressure, high-temperature (HPHT) drilling environments. Reliable, modular, and certified for deepwater operations.

Our components are in service on offshore platforms, land rigs, and remote exploration zones. With support for API standards and OEM compatibility, we keep your rig running.

High-tier assemblies from brands like NOV, Cameron, and Halliburton are in stock and configurable for custom well architectures. Fast logistics, full compliance.

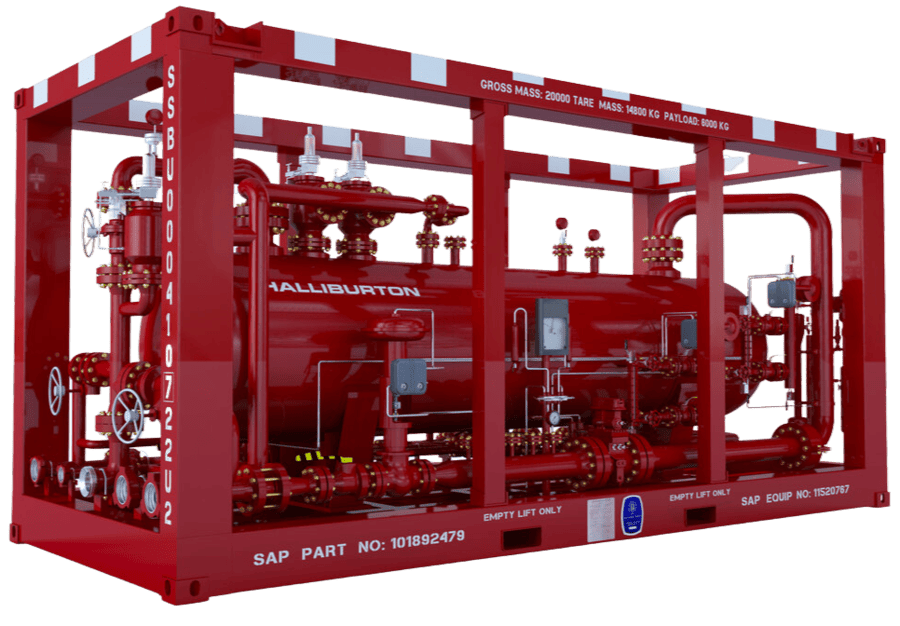

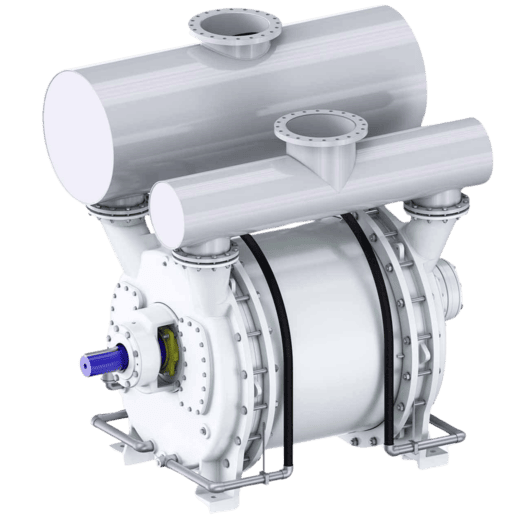

Whether it’s crude separation, dehydration, or gas conditioning — our production skids are engineered for performance in remote and offshore installations. Designed to API and ASME specs, ready to deploy.

Integrated instrumentation, fail-safe valving, and SCADA-ready interfaces. We provide fully packaged systems from trusted OEMs like TechnipFMC, Exterran, and Halliburton.

Separator trains, heater-treaters, coalescers, or electrostatic desalter units — all tailored for your flow rate, fluid profile, and space constraints. Just plug into your process line.

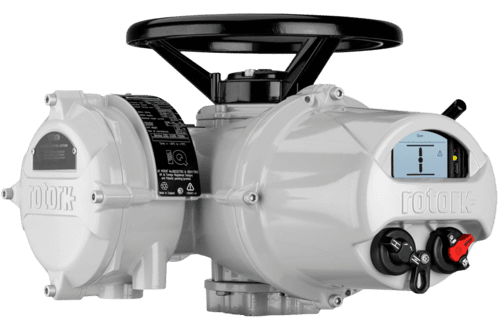

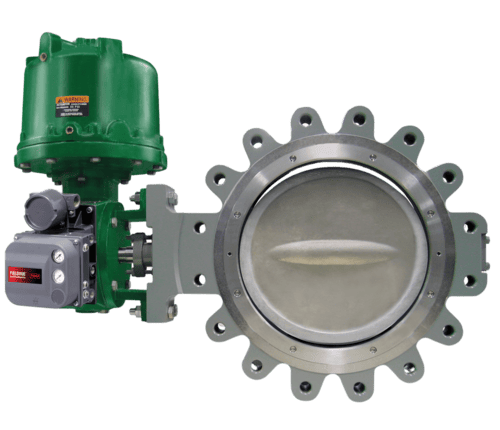

Our electric actuators and control units ensure consistent performance across upstream and midstream installations. With ATEX and SIL-certified models, these systems keep your valves responsive under any load.

We supply critical service choke valves, plug valves, and gate valves for drilling, production, and subsea systems. From ANSI 150 to 2500+, ready for corrosive and high-pressure environments.

From fail-safe spring returns to smart electric actuators with feedback modules — we stock solutions that integrate with SCADA, DCS, and edge control systems for real-time responsiveness.

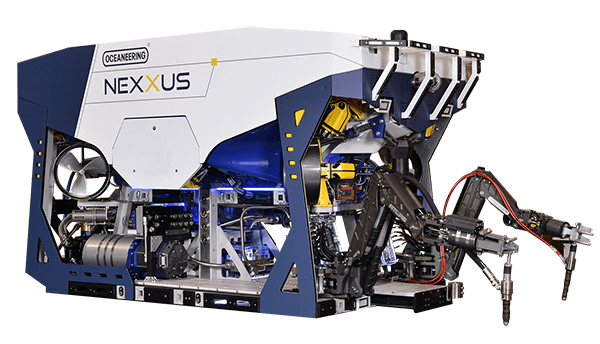

From pipeline inspection to valve actuation at 3,000 meters — our marine and subsea equipment ensures performance where human access ends. We offer ROVs, umbilical termination assemblies, manifolds, and control modules that meet the harshest offshore standards, including DNV, ABS, and API 17.

Our ROV systems, like the Nexxus and Millennium series, provide high-resolution imaging, tool interface modules, and real-time feedback for asset integrity, well intervention, and construction support. Modular, scalable, and designed for full dynamic positioning compatibility.

In addition, we stock critical subsea components such as: stab plates, flying leads, subsea accumulators, hydraulic control panels, and distribution units. All units are compatible with major OEM standards, including TechnipFMC, Aker, and OneSubsea.

Whether you’re building a new tie-back system or maintaining deepwater infrastructure, our inventory and engineering support teams can configure complete delivery packs — from umbilical terminations to ROV-deployable tooling.

Request more information

Reach out to explore partnership opportunities or request a quote. Our team will get back to you within 24 hours.